BW LNG

The world urgently needs to move to a low carbon society. LNG is a part of the solution, and BW LNG creates floating solutions for LNG to support this development.

We are a global company with over 40 years of experience owning and operating LNG assets from offices around the world. After an expansion in the early 2000s which secured us a number of longer-term charters, we now own a fleet of over 30 LNG carriers and Floating Storage and Regasification Units.

We strive to be a true long-term partner for responsible growth, delivering a positive impact for our customers, our communities, our planet, and ourselves, beyond providing competitive solutions for our clients’ gas infrastructure and shipping needs.

LNG Shipping

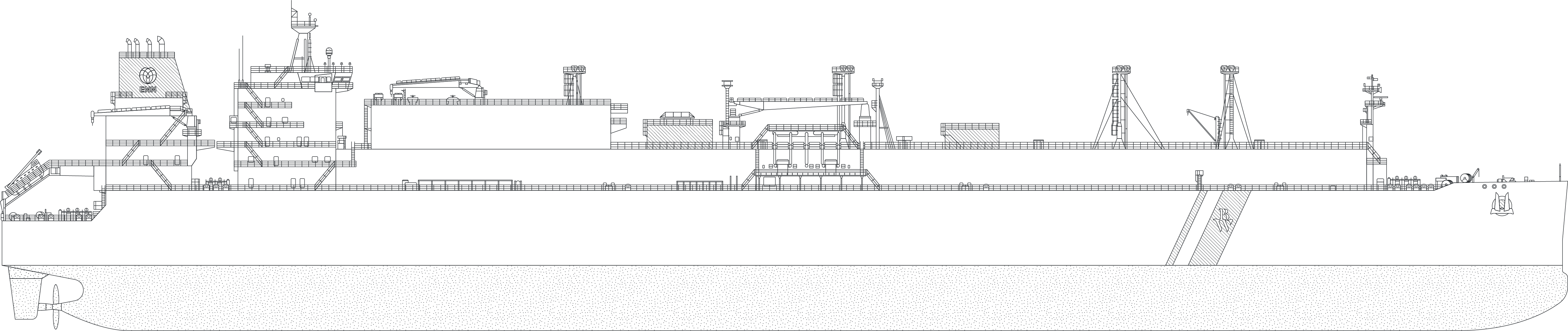

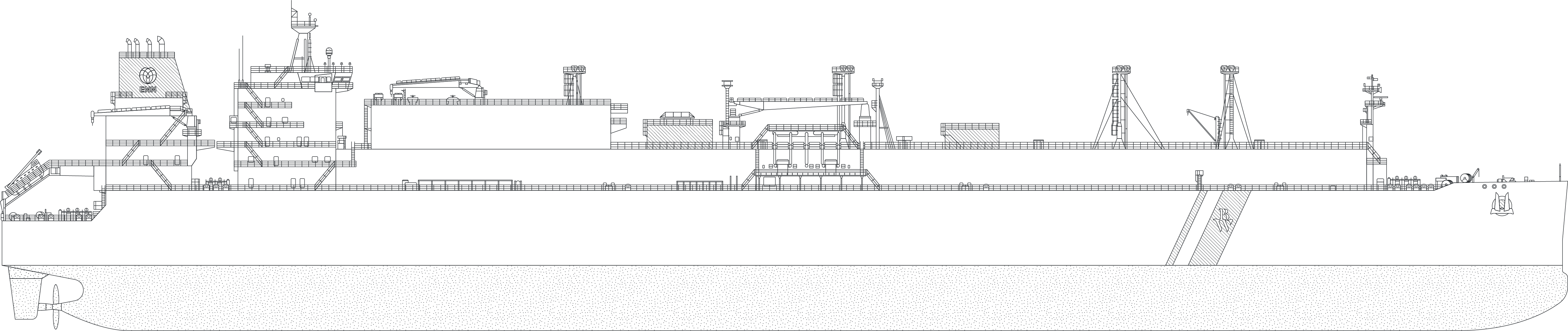

A global pioneer in next-generation, high-tech greener shipping

At BW LNG, we take pride in the design of our vessels and operational standards to achieve best-in-class safety statistics and environmental performance. Since acquiring our first LNG vessel in 1973, we have a long history on operational excellence, maximising fuel and emission savings.

BW’s newest generation LNG carriers are equipped with the latest technology to address environmental issues. The vessels use a MAN ME-GI engine, which, combined with the addition of shaft generators and low methane slip, has reduced the ship’s methane slip by 87% since our first generation ME-GI vessels and up to 11 times less than first generation X-DF LNG carriers.

As part of BW LNG’s commitment to reduce our carbon footprint and emissions, in 2024 we targeted to optimise the performance of our ME-GI fleet and reduce operational costs by leveraging advanced analytics and vessel-specific insights. The deployment of new Power BI dashboards has helped us to identify key areas for improvements in generator performance, HiVAR operations, and PRS/FRS efficiency.

In mid-2025, we plan to introduce a set of operational instructions designed to reduce average fuel consumption by 2–5 metric tonnes of LNG per day and reduce methane slip by 20–30% during HiVAR operation. When implemented, this is expected to achieve an 8% annual reduction in methane emissions while vessels are in transit.

Integrated Gas Solutions

Floating LNG import solutions towards a low-carbon future

Floating storage and regasification units (FSRUs) play a key role in the global transition towards a low-carbon future. Berthed alongside an LNG import terminal, these provide lower-cost, flexible import solutions to strengthen the local gas supply. BW LNG’s floating LNG solutions empower people and communities by increasing their access to natural gas and enabling them to be part of the energy transition.

BW LNG owns four out of 49 FSRUs worldwide, deployed in Brazil, El Salvador, Pakistan, and the Philippines.

Reducing our Environmental Footprint

Route and speed optimisation

In addition to regular maintenance of our existing fleet, BW optimises vessel efficiency by ensuring our ships travel on the most efficient routes at the most efficient speeds. Our voyage optimisation technologies achieve an average of 5-10% potential fuel savings per voyage.

Through harnessing technology and meteorological data to conduct weather routing and regular voyage prognoses, BW ensures the scheduling of our fleet is effective and accurate.

In 2020, our weather routing capabilities were enhanced by the addition of the Total Fuel Oil Consumption (TFOC) system. The system provides an algorithmic calculation and calibration of equipment onboard to optimise speed and routes. BW also endeavours to arrive in ports on time to avoid rushing to arrive, near-shore idling and resultant emissions.

In 2025, BW LNG intends to trial new machine learning based software focusing on voyage and boil-off gas optimisation. This will allow better data-driven decision support for both charterer and owner towards driving reduced emissions.

Safety is our highest priority

Zero Harm to people, the environment, cargo and property

BW is committed to a safe working environment. We do this through a culture of constant communication, active sharing of best practices, learning from near-miss incidents and numerous other safety tools and processes. We aim to ensure that every employee, both onshore and at sea, can work in the safest work environment possible.

Since 2023, our Safety Together campaign has set the course for how we work towards our safety vision of Zero Harm. Safer Together highlights a different topic every quarter, leveraging well-known safety activities for reflective learning and deeper engagement. In 2024, the four topics covered were about dealing with risk, caring for people, following correct procedures and gaining new knowledge.

Since our Zero Harm programme was introduced in 2013, our overall safety statistics have been on a downward trend. Even as we focus on prevention, we remain committed to emergency response preparedness. We conduct regular drills to stress-test our processes, train crew and colleagues, and refine our response as a team.