Navigator Jorf

Transporting Blue Ammonia

Following a long history of safe and successful liquified gas ship-to-ship transfers, Navigator Gas reached a significant milestone this year in completing its first ship-to-ship transfer of anhydrous ammonia (NH3) with Navigator Jorf.

Liquid ammonia has a boiling point at -33ºC. 90% of ammonia production globally is used as a key component in the manufacturing of fertilizers to help sustain food production for billions of people around the world. The remaining 10% of ammonia is commonly used in household cleaning products, refrigerant in air-conditioning units and water purification.

Our specialised gas carriers are some of the most complex oceangoing vessels to operate, and are capable of carrying LPG, Petrochemicals and Ammonia at ambient and refrigerated temperatures. The vessels often change from one cargo grade to another meeting the needs of our customers.

Morgan’s Port Terminal

Largest Ethylene Terminal in the World

Navigator Gas owns 50% of the Morgan’s Point Ethylene Terminal through a joint venture with Enterprise Product Partners. In December 2024, an expansion project to expand the terminal’s capacity for refrigerating, loading and exporting ethylene was completed. The upgraded facility includes a new “flex train” refrigeration unit that triples ethylene refrigeration capacity from 125 to 375 tons per hour – increasing operational flexibility and enabling further capacity additions based on future demand.

Starting in 2025, the terminal is expected to boost annual ethylene export capacity by at least 550,000 tons, reaching 1.55 million tons per year, with the potential to expand up to 3.2 million tons in the coming years. The enhanced capacity continues to leverage the Joint Venture’s 30,000-ton refrigerated storage tank, allowing vessels to load at rates of 1,000 tons per hour. A newly extended and increased offtake agreement with the terminal’s largest customer will support this higher throughput beginning Q1 2025.

Ethylene is the fundamental plastic building block in the chemical industry and is produced through steam cracking. It has a boiling point of -104 ºC. Our ethylene capable vessels are suited to carry this cargo. Propylene, like ethylene, is also a prime building block in the chemical industry and used in a wide variety of finished products. It has a boiling point of -47ºC. Butadiene is primarily used in the production of synthetic rubber and has a boiling point of -5 ºC. These three key petrochemical processed gases make up of the ingredients in the worlds production of processed derivatives which in turn are used in the manufacturing of a myriad end products such as medical equipment, food packaging and textiles.

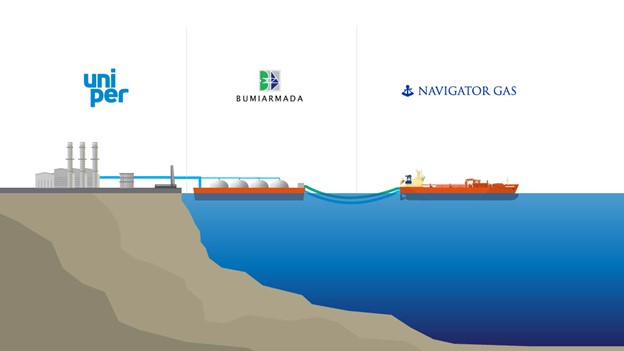

Navigator Gas and Uniper UK

Joint Study on Export of CO2 Emissions from UK Carbon Capture Plant

Bluestreak CO2 (a 50/50 joint venture between Navigator Gas and Bumi Armada) has entered an MoU with Uniper (UK) to investigate solutions to help meet the UK Government’s aim of decarbonising the power sector by 2030.

All parties involved will collaborate to explore the feasibility of implementing a jetty-moored floating liquid CO2 storage facility and liquid CO2 carrier solution for CO2 export from Uniper’s proposed Grain Carbon Capture project on the Isle of Grain, UK. This project aligns with Navigator Gas’ ESG objectives as well as the UK’s Industrial Decarbonisation Strategy.

By leveraging the combined expertise of Navigator Gas and Bumi Armada, this collaboration aims to create a comprehensive value chain for the transport and storage of liquid CO2. The goal is to safely and reliably manage CO2 emissions, contributing to our shared vision of a sustainable future.