Reshaping our Climate Future with Carbon Capture and Storage

The world is responding to the urgent need to manage climate change and move towards a clean energy future. To meet climate goals set out in the Paris Agreement, carbon capture and storage or CCS is an important part of the solution.

CCS is an established technology and capture hubs are being developed. But we will need more than 20 times the current capacity by 2030 to meet ambitious climate goals. About 10-20 large hubs must go on-stream every year if we are to succeed. Most emitters are located onshore. But most of the projected CCS storage capacity will be located offshore.

This presents a unique challenge, and a unique opportunity.

Strength As a Group

Leveraging over 90 years of collective experience

At BW Group, we leverage over 90 years of collective experience in project execution; operation of vessels, floating gas infrastructure and offshore production systems, as well as management of oil & gas reservoirs. With our combination of shipping and offshore competencies, we offer customers safe and cost-efficient end-to-end carbon sequestration solutions.

We can simplify and de-risk our customers’ CO2 emissions management process, by supporting the shipping and storage of LCO2 as part of overall efforts to decarbonise. Here’s how this can work.

Shipping Competencies

BW controls a fleet of over 450 vessels transporting oil, gas and dry commodities, with its 200 LNG and LPG ships constituting the largest gas fleet in the world.

Offshore Competencies

BW has over four decades of experience in operating advanced offshore production systems and executing complex projects.

Supporting the shipping and storage of Liquefied CO2

De-risk overall efforts to decarbonise hard-to-abate sectors

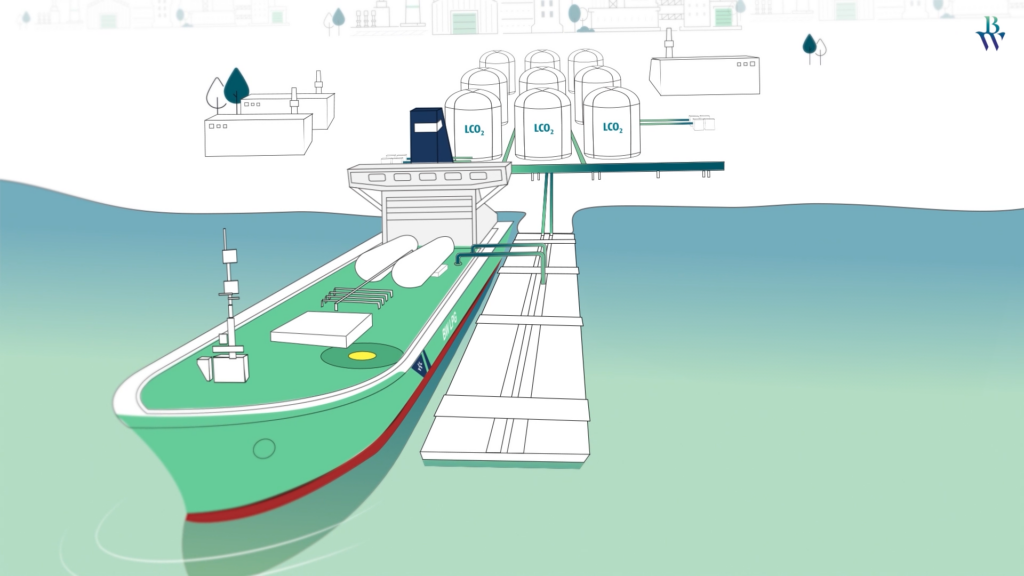

Captured CO2 is piped to shore facilities where it is liquefied, stored and transferred to CO2 vessels; which then sail to injection facilities located onshore or offshore.

These vessels can offer significant advantages over pipelines, especially where long distances make pipelines uneconomical. CO2 vessels also offer more flexibility. They can onboard new capture projects quickly and add capacity with minimal investments in new infrastructure. At the injection facilities, vessels discharge the LCO2, which is reinjected into storage deep underground.

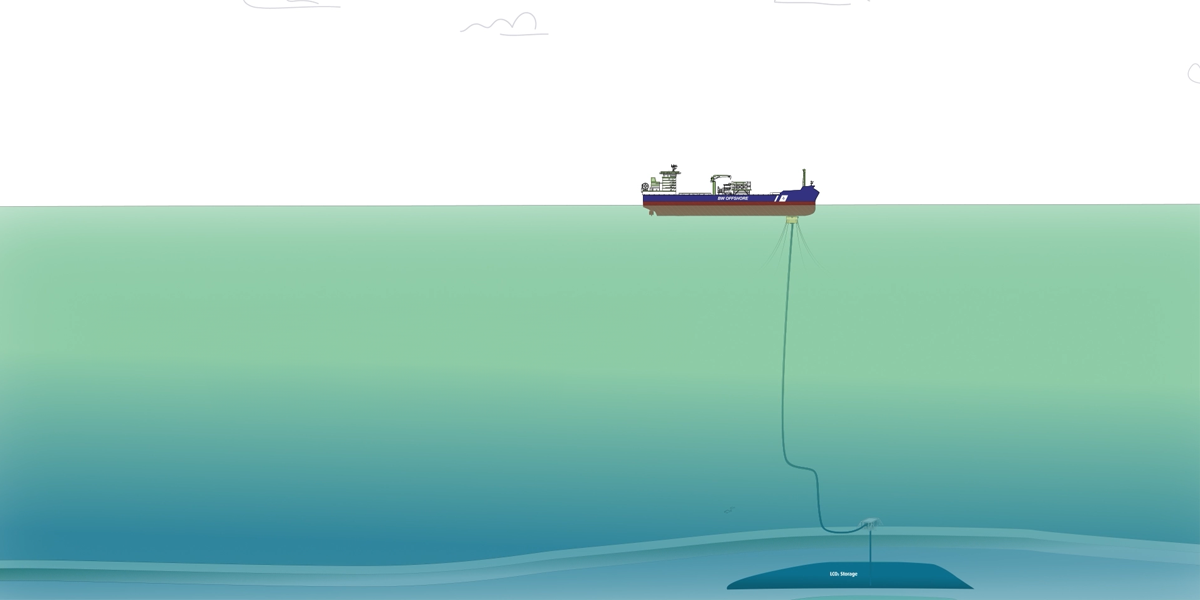

We can offer floating injection facilities as a flexible and cost-effective alternative to fixed infrastructure. They can be deployed and redeployed where there is no existing pipeline, which reduces capital expenditure and shortens lead time. They will also incorporate buffer storage to smooth out intermittent shipping flow and simplify reservoir management.

What does the future of clean energy look like? Brighter. With human ingenuity, global cooperation and advancements in technology, it will be a future where climate-changing emissions are reduced and removed.

Shipping has a complementary role

A flexible option to pipelines

CO2 storage sites are often far away from producers. While the majority of CO2 will be transported by pipelines, this may not be possible or economical for all locations and distances. This is where shipping can play a complementary role.

These vessels can offer significant advantages over pipelines, especially where long distances make pipelines uneconomical. CO2 vessels also offer more flexibility. They can onboard new capture projects quickly and add capacity with minimal investments in new infrastructure. At the injection facilities, vessels discharge the LCO2, which is reinjected into storage deep underground.

Floating Injection Facilities

Flexible and cost-effective alternative to fixed infrastructure

We can offer floating injection facilities as a flexible and cost-effective alternative to fixed infrastructure. They can be deployed and redeployed where there is no existing pipeline, which reduces capital expenditure and shortens lead time. They will also incorporate buffer storage to smooth out intermittent shipping flow and simplify reservoir management.

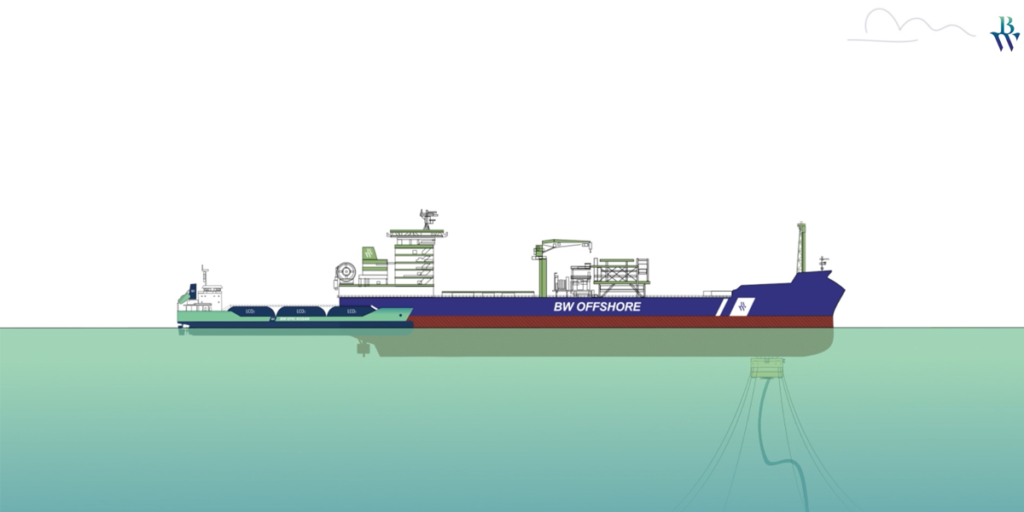

BW Offshore’s Floating CO2 Storage and Injection Unit can provide a flexible, cost-effective alternative to fixed injection infrastructure.

BW Epic Kosan

BW Epic Kosan is a world leader in the last-mile delivery of LPG, petrochemicals and other specialty gases. We have the scale, fleet and operational resources to serve our customers globally; with approximately 3,000 cargo operations annually, we transport >4.7 million tonnes between >300 different ports worldwide.

BW Offshore

BW Offshore leverages over four decades of experience in operating advanced offshore production solutions and executing complex projects. We are actively engaged in the energy transition by developing clean energy production solutions, applying our offshore engineering and operations capabilities to drive future value creation.

BW LPG

BW LPG delivers cleaner energy for a sustainable world. As the world’s leading owner and operator of LPG carriers with five decades of operating experience, we champion competitive, sustainable LPG shipping solutions to secure enduring value for our society and stakeholders.